Why Martenstic microstructure? ; 85% of the abrasive producers in the world manufacture in martensitic structure. The remaining 15% is cast iron, stainless and bainitic structure. Martensitic structure is the most common form of production and it is the latest technology. High carbon steel balls are produced by adding extra carbon, manganese and silica into the raw material, melting them in an induction furnace at 1600 - 1650 ° C and cooling in water after atomization. After casting, the balls are annealed at a certain degree in annealing furnaces and poured into water to create a martensitic structure. Meanwhile, the hardness of the balls is around 63 HRC. Steel balls and grit in martensitic structure can be reduced from 63 HRC hardness to 40 HRC hardness in temper furnaces after the heat treatment they undergo. The main thing in sandblasting is that the hardness of the sandblasting balls and grit used should be at least 3 - 5 HRC harder than the sandblasted surface, so that the cleaning and roughness to be obtained on the surface can be faster and with the desired properties. Using balls of lower hardness than the hardness of the sandblasted surface extends the blasting time and cannot perform the desired cleaning. This situation causes an increase in labor and energy consumption in the sandblasting process. In the cost of the blasting process, the blasting material only constitutes 10-15% of it. The remaining 85-90% is labor and energy expenses. For this reason, the selection of suitable hardness and grain size material is of great importance in terms of process cost. Martensitic structure is a type of production that enables production at hardness values between 40 - 63 HRC. Our company's expert technical team will be happy to assist you.

Application Areas;

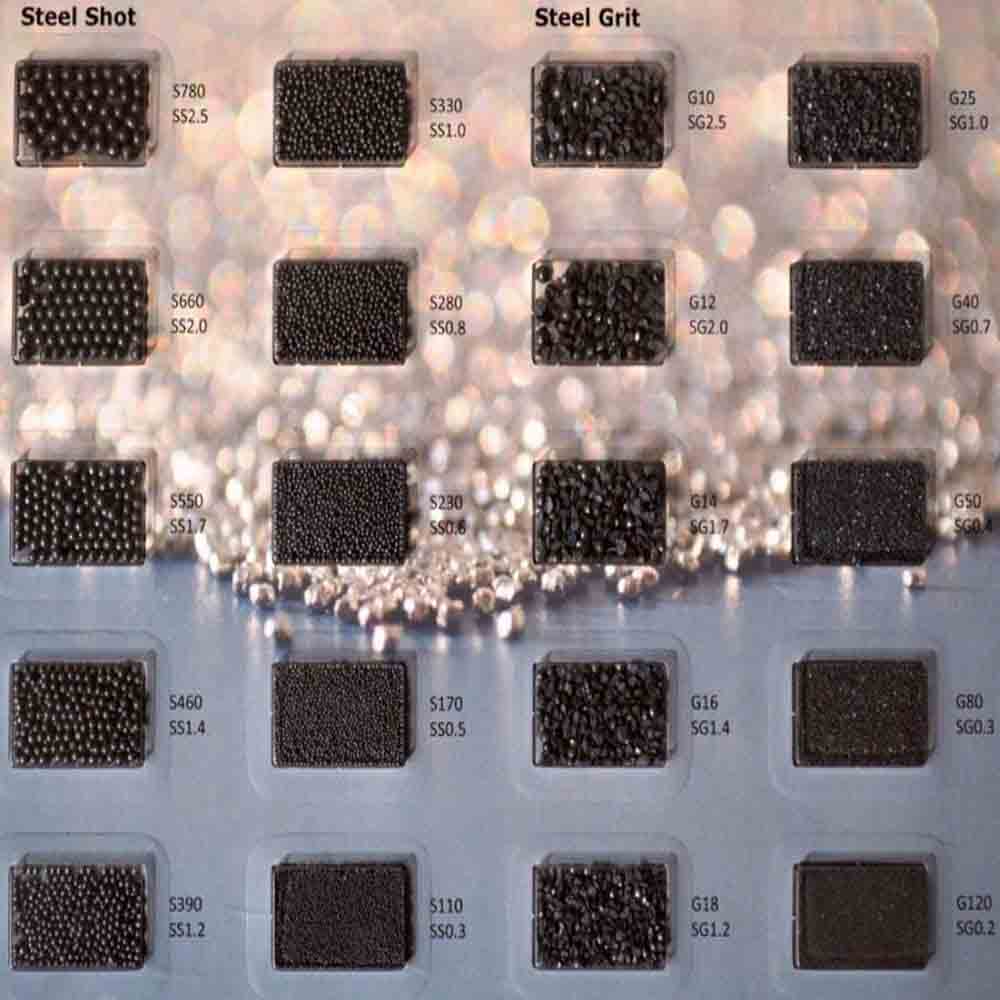

High carbon steel grit for surface treatment is a very strong abrasive compared to steel balls. High carbon steel grit is a high quality metal abrasive, extremely durable and economical. High carbon steel grit is produced by breaking the High carbon steel ball after full heat treatment. It is characterized by very low dust emission and extreme durability compared to sand, slag and mineral abrasives. Grit gives a much sharper roughness profile than steel balls, which ensures proper adhesion of the protective coating to the surface and effective removal of heavy paint. High carbon steel grit is used to clean the surface of steel, cast iron and cast steel before coating or bonding, descaling and rust removal, deburring, anchoring pattern.