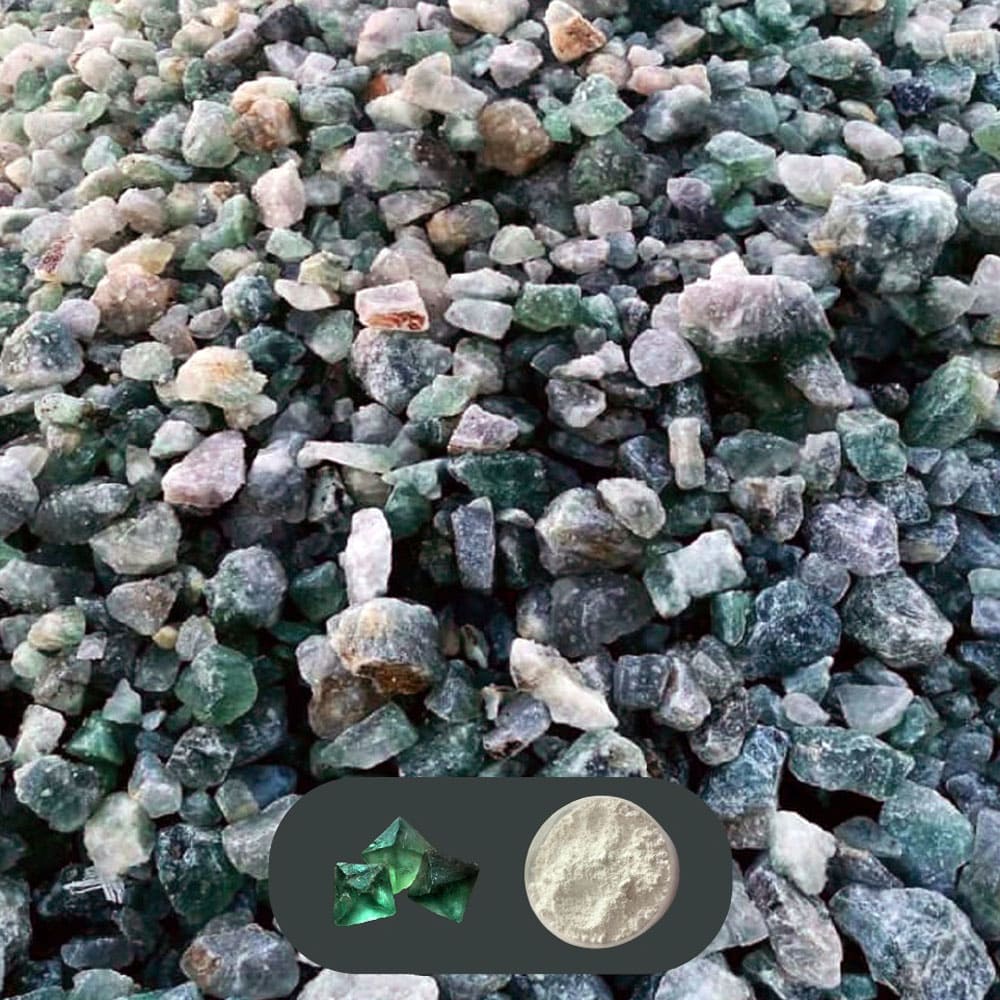

Fluorite is in the composition of (CaF2) Calcium fluoride and when pure it contains 51.3% Calcium and 48.7% fluorine. Since it is used as a slag maker in metallurgy and has a low melting point, it comes from the Latin word fluere (flow). It crystallizes in cubic system, mohs hardness is 4, specific gravity is 3.18 gr / cm3, melting temperature is 1330ºC, its color is purple, green, blue, yellow, white, pink, brown and bluish black, transparent translucent mineral. Colors vary depending on the impurity element in the crystal lattice. Fluorite also contains rare earth elements that fluoresce and affect color properties. It shows blue or purple fluorescence under cathode and ultraviolet light. It shows phosphorescent properties when heated. Our company's expert technical team will be happy to assist you.

In the commercial field, fluorite can be divided into three classes;

1. Used in acid industry (Asitspar or Acid class)

2. Used in the chemical industry (Seramikspar or Ceramic class)

3.Used in metallurgy industry (Metspar or Metallurgy class)

Hydrofluoric acid produced from fluorite with more than 97% CaF2, defined as acid grade, is the raw material of many industrial products. Chlorofluorocarbons, tri and dichlorofluoromethane and ethanes used as coolants, foam blowers and solvents are the main chemicals produced from acid-grade fluorite.

Fluorite with 80-96% CaF2 content, defined as ceramic grade fluorite, is used in ceramic (3%), glass (10-20%) enamel (3-10%) industry. They are used in the production of glaze in the ceramic industry, in the production of white and colored opal glass in the glass industry, in the production of portland cement in order to obtain clinker, in the coating of the steel parts of stoves, refrigerators and cooking appliances, in the production of glass wool. HF is the main raw material in the production of aluminum fluoride and synthetic cryolite, which are used in the metallurgy industry and mainly in the production of aluminum metal by electrolysis.

Fluorites with 60-85% CaF2 content, defined as metallurgical grade, are used to reduce slag surface pressure in steel production, to reduce melting temperature and slag viscosity, to remove unwanted iron from Si, S, P and C by passing them into slag and to prevent the corrosion of refractory bricks. Apart from the steel industry, it is used as a binding agent in the production of abrasives. It is used in the production of fluorite, artificial rubber and aerosol, in the production of Mg & Ca metal and in many industrial branches, as well as as a substitute for rutile in electrode coatings.